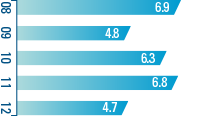

RAW STEEL PRODUCTION (Million tonnes)

In August 2011, BlueScope announced it was restructuring its Australian operations and would largely exit the Australian export business.

Key features of the restructure included:

- Shut-down of No.6 Blast Furnace at Port Kembla, with annual production reduced to 2.6 million tonnes.

- Closure of No. 4 Coke Ovens Battery, No. 3 Basic Oxygen Steelmaking (BOS) furnace and No. 1 slab caster.

- Closure of the Hot Strip Mill and mothballing of Metal Coating Line No.5 at Western Port.

The technically complex decommissioning work was conducted safely and successfully, and without any significant environmental impact. The effect of the closures on the Company's environment footprint has been profound and is evident throughout this report. Absolute levels of environmental impact such as emissions, and energy and water consumption have been reduced, while intensity based metrics have increased. Bluescope will continue to develop initiatives directed at reducing these metrics.

The reporting period of this Community, Safety, Environment Report spans the transition to 2.6 million tonnes annual steel production. A full picture of BlueScope’s environmental footprint at reduced production levels will be seen in the 2013 Community, Safety, Environment report.

We will achieve improvements in our environment footprint through:

- Fostering and promoting a continuous improvement culture

- Capital investment to maintain and improve our equipment and facilities

- Robust systems to manage our responsibilities

Even in difficult economic times, our commitment to caring for the environment remains strong and the performance of a number of BlueScope sites has been recognised by external bodies:

- Many BlueScope Steel sites maintain ISO 14001 certification.

- Continued membership of the World Steel Association Climate Action program, as participants in the worldsteel CO2 data collection program.

- Cilegon, Indonesia received award for plant with cleanest environment

- Kapar, Malaysia shortlisted for Federation of Malaysia Manufacturers Manufacturing Excellence Award.

- New Zealand Steel finalist in the Ministry of the Environment's Green Ribbon Awards.

- Map Ta Phut, Thailand received an Excellent Environmental Management Award presented by the Industrial Environmental Authority of Thailand.

We manage our environmental risks and impacts through the use of a framework we call LAWWNE, which seeks to:

- Reduce our environmental impact on Land, Air, and Water

- Reduce generation of Waste and Noise

- Minimise our use of Energy and the generation of greenhouse gas emissions

Through the use of this framework we also seek to conserve scarce resources by reusing and recycling material.

We are committed to monitoring and publicly reporting on our progress through our participation in independent external reporting initiatives, such as Australian National Greenhouse and Energy Reporting and the National Pollutant Inventory, and through initiatives such as this Community, Safety and Environment Report.

This Report provides comprehensive information about BlueScope Steel and the environment, including governance and policy arrangements, and performance measures. The Report is structured around our LAWWNE framework.