In many of our manufacturing activities throughout the world, process disturbances have the potential to lead to air emissions. Throughout decades of operation, BlueScope has reduced the number of process disturbances leading to air emissions, as well as the extent of emissions when process disturbances do occur. The Company aspires to extend this improvement record in order to eliminate all air emissions from process disturbances.

Clean air is essential to all living organisms. BlueScope is committed to improving air quality in the communities where we operate and aspires to continually lower all types of emissions to air.

Current controls

BlueScope has installed control mechanisms to reduce emissions at many facilities, including:

- Baghouse / filtration systems

- Chemical treatment

- Thermal oxidisation

- Scrubber systems

- Dust suppression

The Company extensively monitors emissions at its operations, both on and off site, to understand community impact, identify improvement opportunities, and maintain compliance with regulatory limits.

A number of facilities are required to report air emission data to regulators. Depending on the regulatory framework, emission data may be published.

Performance

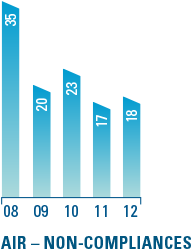

Through diligent operational management and engineering, BlueScope has successfully reduced the number of non-compliances relating to air by almost fifty per cent over the past five years. During FY2012, there were 18 air related non-compliances reported to regulators, and no significant air related incidents.

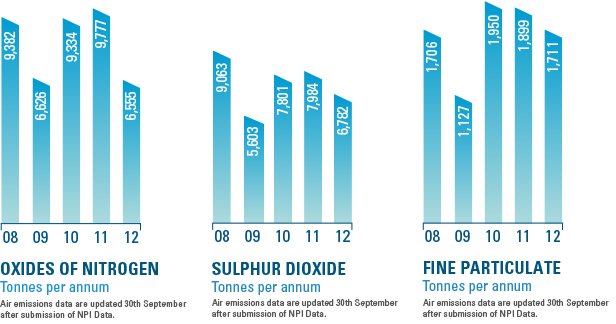

Three key pollutants have been selected to monitor and report across the Company, Particulate Matter less than 10 microns (PM10), Oxides of Nitrogen (NOx) and Sulphur Dioxide (SO2). Emissions of these pollutants are either measured at the source or estimated based on emission factors and operating data.

During the first quarter of FY2012, BlueScope closed operating units at the Port Kembla Steelworks and at the Western Port Works, resulting in reduced emissions to air.

The increase in reported fine particulate emissions from FY2010, as shown in the graph, reflects the inclusion of estimated fugitive dust emissions from vehicle movements and stockpiles at the Port Kembla Steelworks.

Reduced air emissions in FY2009 reflect lower production levels due to the No 5 Blast Furnace reline and global financial crisis.

Fines & Prosecution

An incident occurred in February 2012 resulting in two fines of $1500 each, issued by the regulator in March 2012. The incident related to operations at the Basic Oxygen Steelmaking (BOS) plant at the Port Kembla Steelworks, where the BOS plant continued to operate after the dedusting baghouse fan tripped on high vibrations and stopped operating. Whilst the baghouse was not operating there were several emissions from the BOS roof. Investigations identified that the relevant alarm had failed to operate.